Everest Twin and Tri Lobe Blowers and Acoustic Enclosure:

Our company has 20 years' experience

Twin & TRI Lobe Rotary Blowers

We are an authorised Channel Partner & distributor of EVEREST (IR Company) Blowers.

Everest Blowers & Vacuum Pumps – An Ingersoll Rand Business was established with the purpose of empowering our customers’ Industrial Low Pressure & Vacuum needs and providing them with Innovative Cost-Saving Engineering Solutions.

Established in 1980 , Everest Group has served more than 4000+ unique customers across 40+ countries and helped our customers save more than 5000+ Cr in their profits & reclaimed more than 3,50,00,000 productive hours.

Applications:

- Water Treatment Plants – Back washing of filter/mixed beds

- Effluent Treatment Plants – Diffused aeration and agitation of effluent

- Cement Plants – Blending, aeration, fluidization, conveying

- Aquaculture – Maintaining dissolved oxygen level

- Chemical Plants – Supplying process air

- Electroplating Plants – Oil-free air agitation of electrolyte

- Paper Plants – Knife edge coating, drying, conveying, vacuum pickup

- Yarn Drying – Vacuum/Pressure drying of yarn

- Vacuum Moulding – Creating quick vacuum

- Polyester Chip – Conveying & drying

- Bag Filters – Reverse cleaning of filter bags

- Pneumatic Conveying – Vacuum, pressure, and combination conveying of cereals, cement, husk, baggage, granules, powders, etc.

- Regeneration – Dryers & molecular sieves

Salient Features & Advantages:

- 100% Oil free air delivery

- Factory engineered, guaranteed & superior product

- Rigid one-piece CI Casting & Side Plates

- Design & manufactured with precise CNC machines to maintain close tolerances

- Minimum slippages and higher output efficiency

- Low noise and vibrations

- Low internal friction and reduced frictional heat

- Robust shaft designs to withstand high load

- Each machine tested as per BS 1571 Part II

- Rotor balancing as per Gr 6.3 ISO 1940/1 (1986)

- Proven designs having decades of PTR

- Readily available after-sales support and spares

SIDE CHANNEL / RING BLOWERS

We are an authorised Channel Partner & distributor of EVEREST (IR Company) Blowers.

Everest Blowers & Vacuum Pumps – An Ingersoll Rand Business was established with the purpose of empowering our customers’ Industrial Low Pressure & Vacuum needs and providing them with Innovative Cost-Saving Engineering Solutions.

Established in 1980 , Everest Group has served more than 4000+ unique customers across 40+ countries and helped our customers save more than 5000+ Cr in their profits & reclaimed more than 3,50,00,000 productive hours.

Everest Side Channel / Ring Blowers :

Salient Features & Advantages:

- 100% Oil Free and Dry Quality Air, safe for critical applications. First choice in many automation projects for applications requiring Low & Medium volumes of clean, dry air at low pressures and vacuum.

- Bottom Mounting Base Design to reduce Vibration & Noise. Low noise operation (64-88db(A)) with small footprint (compact) & virtually maintenance free design. Low vibration.

- Constructed from Die Cast Aluminium Alloy. All our blowers are extremely robust, corrosion resistant and are suitable for the most demanding applications.

- Available in single/three phase configuration & single/double/triple stage design.

- Designed for continual use up to a maximum ambient temp of 45°C - 50°C.

- Equipped with low-noise, high-efficiency, Class F, IE2/IE3 Induction Motors (50/60 Hz Dual Frequency).

- Direct Driven: maximize energy efficiency by eliminating gears or transmission box losses.

- Zero maintenance cost: Our blowers do not use gearboxes and oil lubricants used by conventional blowers, minimizing maintenance requirements, lowering user maintenance costs and improving overall system stability. Direct Driven, hence maximize energy efficiency. In addition, by adopting air-cooled cooling, there is no need for cooling water circulation and associated maintenance cost.

- Everest Side Channel Blowers suitable for vertical and horizontal operation. Full ATEX range available.

AREA OF APPLICATIONS:

- Sewage Treatment Plants

- Water Treatment Plants

- Electroplating Plants

- Aeration

- Air Knife Systems

- Vacuum Conveying

- Vacuum De-Solders

- Vacuum Lifting & Feeding

- Screen Printing Machine

- Dust Collectors Machine

- Offset Printing Machine

- UV Coating Machine

- Paper Folding Machine

- Mini - Offset Printing Machine

- Pneumatic Conveying Machine

- Paper Cutting Machine

- Vacuum Forming Machine

- Sealing Machine

- Labeling Machine

- Filling Machine

- Bottling and Canning

- Food Processing and Packaging

- Pharma, Medical, Nutra

- Extrusions

- Industrial Products

- Electronics and Solar

- Ceramic

- Refractories manufacturing

- And many more.

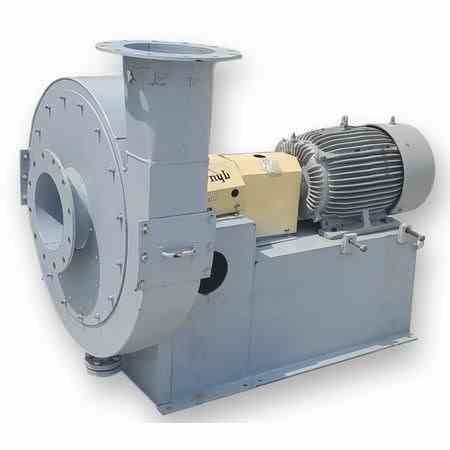

CENTRIFUGAL BLOWERS AND FANS

Everest Aluminum Centrifugal Blowers have been successfully used for decades in many markets for a wide variety of functions. The consistent high quality and solid construction ensures a quiet and sustainable operation that is highly appreciated by users.

Centrifugal Blower/ Fan :

Salient Features & Advantages:

- High strength Aluminium alloy for lightweight, high volumes of clean, oil-free, dry air at low pressure and vacuum.

- For the same power, the airflow is 10 times higher than Side Channel Blowers, with limited pressure.

- Adjustable outlets & motor position.

- Available in single/three-phase configurations.

- Low noise operation.

- Virtually maintenance free.

- Extremely robust, corrosion resistant, and suitable for demanding applications.

- Designed for continual use up to 45°C to 50°C ambient temperature.

- Equipped with low-noise, high-efficiency, class F insulated IE2/IE3 induction motors.

- No oil operation, no vibration.

- 100% Oil-Free and Dry quality air, safe for critical applications.

- Performance based on actual tests, not just calculations.

- Zero maintenance cost—no gearboxes or oil lubricants.

- Air-cooled system eliminates the need for water cooling systems.

- Direct Driven Blowers – no gears or transmission boxes.

- Suitable for vertical and horizontal operation.

- Customizable for High Temp (Up to 200°C), Variable Sizes, and Special Voltages.

- Full ATEX range available.

AREA OF APPLICATIONS:

- Combustion air suppliers

- Drying and cooling systems

- Dust control

- Air conveyor systems

- Fluid bed aerators

- Clean air circulation

- Material handling

- High-temperature operation

- Saturated air processing

- Exhaust

- ID / FD Fans

- Cooling

- Air-cleaning

- Drying

- And many more

Spares

100% inhouse manufacturing.

Buy only GENUINE Everest Products.

Retain your advantage with factory genuine replacement parts & accessories. All parts meet original manufacturing specifications and tolerances for guaranteed fit and function. Pre-packaged overall kits with detailed service manuals are available on request.

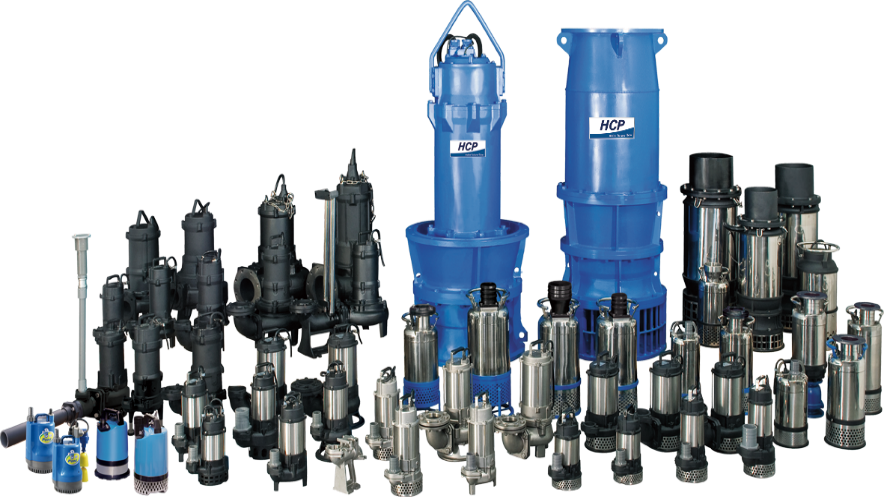

Pumps

Energy Conservation, Environmental Protection and Pump Technology Development

Provide the best product and service for our customer by our professional skill, innovation and improvement. Dedicate ourselves to become the leading brand by developing 【high-efficiency pump application】 and take care of the earth!

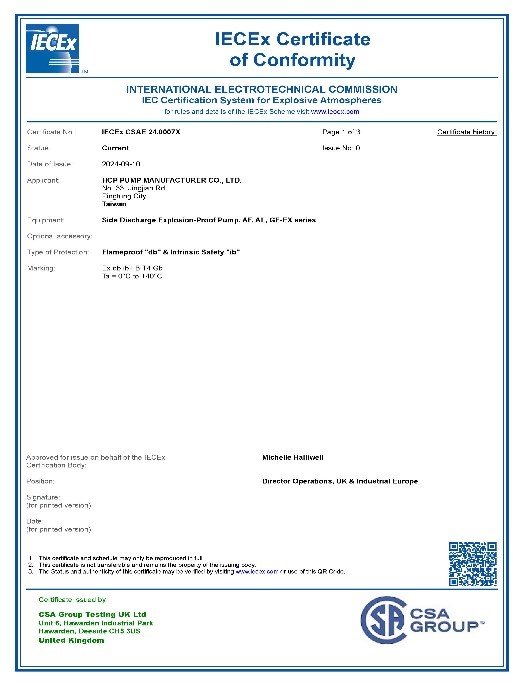

Established in 1979, HCP PUMP MANUFACTURER CO., LTD. is Taiwan's most successful submersible pump manufacturer. HCP has maintained a dedicated and enthusiastic team committed to advancing hydrodynamic technologies with reduced consumption. Our unwavering commitment to excellence extends to providing unparalleled customer service, aiming to achieve the highest satisfaction for domestic and international customers.

HCP pumps are widely used across various sectors, including dewatering, gardening, agriculture, aquaculture, construction, plant sewages, flood control stations, and mining.

Centrifugal Blower/ Fan :

CERTIFICATION :

APPLICATIONS:

- Process water

- HVAC

- Cleaning

- Firefighting

- Industrial water supply

- Industrial Boosting

- Industrial Boosting

- Irrigation

- Drainage / Sewage Dewatering

- Aquaculture Farming

- Construction sites

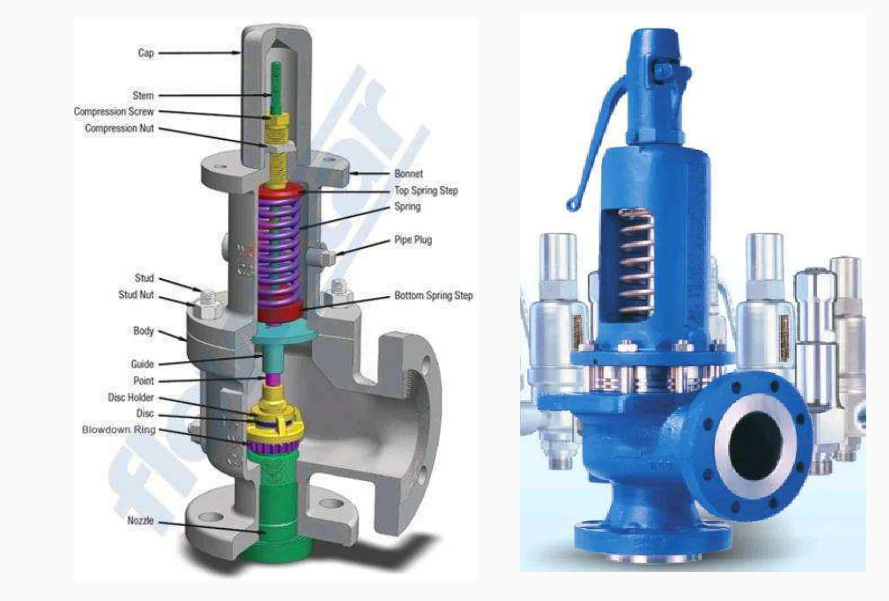

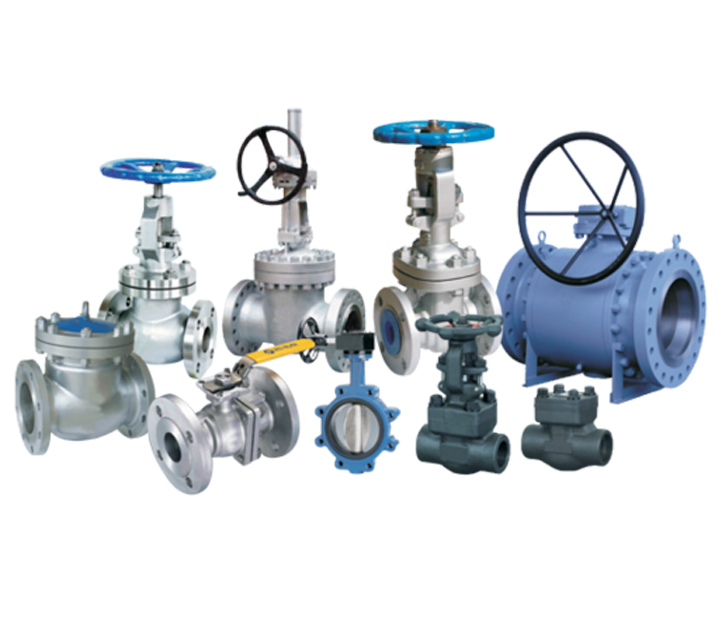

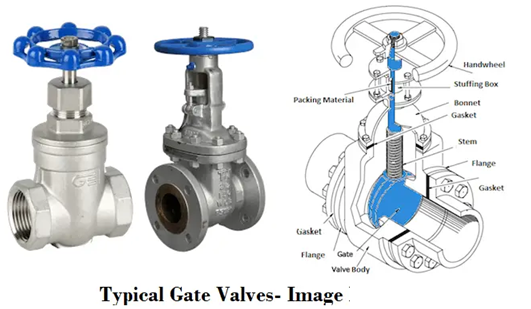

MANUAL VALVES

Type of Valves:

Gate Valves, Globe Valves, Check Valves, Ball Valves, Butterfly Valves, Plug Valves, Piston Valves, Knife Gate Valves, Bellowseal Valves, Steam Traps, Flush Bottom Valves, Safety Valves, Blow Down Valves, Feed Check Valves, Control Valves, Diaphragm Valves, Strainers, Pressure Reducing Valves, Solenoid Valves, Sight Glass, Liquid Level Gauge.

MANUAL VALVES:

Material of Construction:

- ASTM A395 Gr Ductile Iron

- CAST IRON TO IS 210 GR.260

- ASTM A216 Gr WCB

- ASTM A351 Gr CF8

- ASTM A351 Gr CF8M

- ASTM A351 Gr CF3

- ASTM A351 Gr CF3M

- ASTM A351 Gr CN7M Alloy20

- ASTM A352 Gr LCB

- Argonite

- ASTM 351 Gr CD4MCu Duplex Steel

- ASTM A494 Gr CW6M Hastelloy

- ASTM A494 Gr CW9M Hastelloy

- ASTM A494 Gr CY40 Inconel

- ASTM A494 Gr CZ-100 Nickel

- ASTM A494 Gr M30-C Monel

- ASTM B148 Gr 985 In-Al Bronze

- ASTM B367 Gr C-3 Titanium

- ASTM B 61 Bronze

- BB752 Gr 702 Zirconium

Coating:

ENP, Nylon 12, Aroxy, PFA, PTFE, HDPE, Rubber, 13% CR, Heat resistance paint, Stellited